PRODUCT

R & d manufacturing and sales of precision intelligent high-tech enterprises

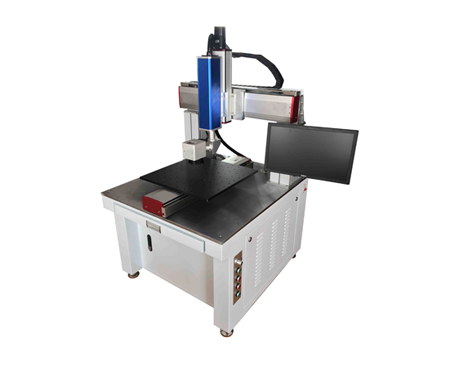

Minimum aperture to 0.02mm, suitable for metal and ceramics and other precision micro hole processing.

Lasers, high power fiber laser galvanometer laser, high speed precision deflection with precision telecentric lens focus, implementation of sheet material (less than 1 mm thickness, aluminum, copper, stainless steel, all kinds of ceramic, etc.) high speed precision cutting perforation and impact perforation, through the straight line XY platform extension processing level, the consistency of the hole, cutting smooth and verticality of hole wall.

1. Carefully select high power infrared fiber laser ablation material, the minimum 20 microns processing spot

2. High speed and high precision control beam deviation through precision galvanometer to realize small format high speed and high precision etching processing

3. Realize large-area precision processing through separate gantry XY precision platform translation

4. The z-axis is electrically adjustable to adapt to materials of different thickness and meet the requirements of three-dimensional structural etching

5. Side-axis high-resolution industrial cameras are optional to achieve high-precision positioning and large-area precision splicing processing.

6. It can be used for processing metal and ceramic materials, realizing etching, blind hole, through hole, grooving, cutting, etc

7. The minimum processing line width (aperture) of 20 microns, the processing range of 300*300mm can be customized

8. All parts are carefully selected to meet the industry 24/7 continuous operation

Application:

Consumer electronics, instrumentation, microelectronics components manufacturing, mold molding

Scan, stay tuned

Our latest news