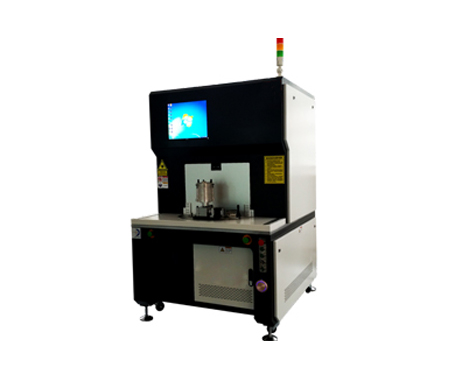

PRODUCT

R & d manufacturing and sales of precision intelligent high-tech enterprises

Product features:

A perfect replacement for ultrasonic welding plastic welding process, high-speed, clean, accurate, reliable, economic.

Adopt quasi-synchronous "laser transmission welding" method, equipped with special large-caliber high-speed laser scanning galvanometer, high power, high beam quality laser, full use of laser energy, high welding efficiency.

The laser beam can control deflection scanning in X and Y directions according to the graph data, and the maximum scanning speed can reach 2000mm/s. Due to the fast scanning speed, the material will melt along the whole welding line, and the welding parts will be welded almost at the same time along the welding seam. The laser provides energy continuously until the specified welding requirements are met.

High precision depth measuring device can be added to qualitatively and accurately evaluate welding process results.

A synchronous pyrometer can be attached to reliably identify any abnormalities in the welding line and welding temperature.

Product advantages:

1. High welding efficiency and reliability;

2. The whole welding line is plasticized at the same time, and the welding depth is controllable;

3. During the welding process, the product does not need to move;

4. Scanning track digital programming has high accuracy and flexible control;

5. Suitable for components within 200mm x 200mm;

6, compared with other methods, significantly reduce the cost of mold.

Suitable materials: ABS, PP, PE, PA, PC, PS, PVC, PBT, POM, PET, PMMA and other thermoplastic materials and various modified engineering plastics.

Application fields: plastic auto parts, plastic medical instruments, plastic shell of electrical and electronic products, lighting products, etc. It is especially suitable for sensors and electronic components that need reliable sealing.

Scan, stay tuned

Our latest news