NEWS

R & d manufacturing and sales of precision intelligent high-tech enterprises

Laser is a new light source in 1960s. Laser is widely used because of its good directivity, brightness and monochrome. Laser processing is one of the most promising fields in laser applications. More than 20 laser processing technologies have been developed. Laser has the characteristics of good monochrome, strong directivity and high brightness. Thousands of types of laser materials have been found, with wavelengths ranging from soft x-rays to the far infrared. The core of laser technology is laser. There are many kinds of laser, which can be classified according to different methods such as working material, excitation mode, operation mode and working wavelength. According to different application requirements, some special techniques are adopted to improve the beam quality and individual technical indexes of the output laser.

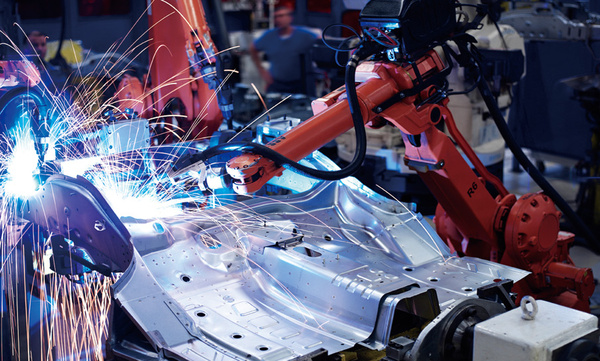

At the same time that laser technology has been developing rapidly, electronic integrated circuit industry and printed circuit industry are also developing rapidly. According to the growth trend of these products with higher technical content, electronic products are constantly improving in terms of independent innovation design and processing technology. In order to obtain more ideal processing effect, high-tech means should be adopted for processing and manufacturing. Laser technology, as an important processing method in the field of precision machining, provides better processing solutions for the electronic industry and many other industries, and is an important direction in the field of processing in the future. Such as laser marking machine, optical fiber laser marking machine, laser welding machine, laser cutting machine and other equipment, are now widely used in the electronic industry, now the electronic industry provides a more quality processing solutions, lean processing technology for the development of the electronic industry now provides more possibilities.

The main advantages of laser processing are:

A. With the computer control laser beam can move at high speed, can improve the processing efficiency, economic benefits;

2. With high processing accuracy, the laser can act on the surface of the material with extremely fine beam, and the narrowest line width can reach micron level.

3. In terms of speed, the laser is processed directly by high energy density laser beam, while the traditional machine processing is complicated.

Four. The workpiece in the closed container can be processed through the transparent medium. Laser processing can be carried out by robots in harsh environments or places inaccessible to others.

Five. For the processing of large quantities of products, the traditional machinery is not stable and the precision is not high; The laser on the contrary, and the workpiece between the action of no machining force, with no contact, no cutting force, thermal impact

Small advantages, to ensure the accuracy of the workpiece, and can be made in a variety of materials on the surface of a very fine mark and durability is very good;

In order to apply laser technology more widely, many laser equipment manufacturers now pay more and more attention to the development of downstream application industry, and constantly increase the investment in research and development, software design, automation improvement and other aspects. With the continuous improvement of laser technology and the transformation of processing methods in many fields, the application of laser technology in many fields will be more and more extensive, and it will have more advantages compared with traditional processing methods.

Scan, stay tuned

Our latest news